Pothole Protection Maintenance

|

|

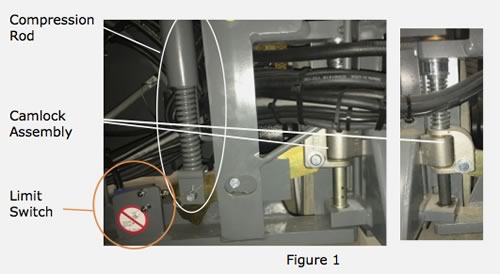

The pothole protection system on the Skyjack SJIII model DC electric scissor lifts is designed to reduce ground clearance and assist in the stability of an elevated aerial platform in the event the aerial platform encounters a “drop-off” or “pothole.” As with all safety devices, periodic inspection and maintenance is required to ensure the proper operation of the pothole protection device. The nature of this safety feature relies on maintaining a consistent ground clearance, therefore, if the aerial platform ever does come in to rest on the pothole device, the platform should be immediately lowered and “locked out” to prevent further use until a complete inspection of the mechanism is performed by a qualified technician. The system is comprised of four major components; the pothole bar (not shown), the camlock assembly, the compression rods, and the limit switches. See Figure 1. |

|

|

The pothole bars are the angle parts located along the bottom edge of the tray on each side of the unit. They deploy by gravity and should pivot smoothly and not be bent or damaged. The most important part of maintaining the system is keeping it clean. Familiarize yourself with how the mechanism correctly operates. Examine the mechanism for damage and debris. Replace any worn or damaged parts. Thoroughly clean the entire mechanism – a pressure washer works best to remove any material that may prevent smooth operation of the mechanism. Operate the mechanism and look for smooth operation of the levers, pothole bars, and camlocks. Test for correct operation by placing a block (approximately 1.5” high) under the swing out tray on one side (preventing the pothole mechanism from fully-deploying). After raising the platform to a height of approximately 7 feet, attempting to drive should result in no movement. This test should be repeated for the other pothole bar. No lubrication is needed for the camlock assembly as it uses oil impregnated bushings. The same applies to the pothole bar pivots under the trays, they use the oil impregnated bushings as well and require no lubrication. Sparingly apply a light spray lube on the limit switch roller plunger, and the pivot pins - too much will attract dirt and debris since this mechanism is close to the ground. For more information regarding the pothole mechanism limit switch adjustment, or replacing the camlock assembly, please visit www.skyjack.com, look under technical manuals and input your model OR serial number and watch the technical animations for those procedures. If you have any questions regarding your Skyjack product, please contact Skyjack Product Support at 1-800-275-9522 or email service@skyjack.com for assistance. |

| TECH TIDBIT |

| Training for your technicians is very necessary to maintain a dependable and safe fleet. Technical training is available for current production equipment at your location from your Skyjack Regional Service Representative. For more information, ask your rep when they stop by, or call 1-800-275-9522 and ask for Rich Soltas. You can also email rich.soltas@skyjack.com. |

|